How to Specify Cleanable Surfaces for Healthcare

For too many years the design profession has been confronted with seemingly insurmountable challenges—an increase in superbugs resistant to cleaning products, deselection lists, environmentally friendly products provided by healthcare surface material manufacturers without a thorough understanding of the complexities of cleaning in the healthcare environment, and now we have to consider the enhanced cleaning required to address novel coronaviruses, all of which have resulted in many products disintegrating at warp speed.

Coated upholstery fabrics which previously could last for years are failing in a matter of months, usually because cleaning products are not being wiped off with clear water, as stated in the manufacturer’s cleaning requirements. This often results in the entire furniture item needing to be reupholstered or put in the dumpster. Previous expectations of furniture lasting 10 or more years have been lowered to five to seven years, with many pieces failing in less than six months.

These failures include:

- Coated upholstery materials: splitting, cracking, crocking, peeling, puddling, fraying, fading, staining and delaminating, and becoming sticky/gummy

- Flooring: yellowing, peeling, becoming sticky/gummy, splitting, bubbling, puckering

- Wood: protective coatings when removed leave the finish sticky and gummy, and the stain color disintegrates, leaving exposed raw, open pore wood

With the onset of COVID-19 and new cleaning products and protocols, many of the issues formerly found primarily in healthcare and hospitals are now being seen in retail stores, schools and universities, hotels, and nursing homes. It is not uncommon for workstation chairs to be used 24/7 by three shifts of workers, each person cleaning their chair with a combination of hospital grade wipes, their own bleach wipes and/or other products that cause premature degradations and complete failures. This is an unsustainable operating paradigm, so what can we do?

Before we can understand why these materials are failing, we must first understand how cleaning and disinfection is typically performed in the real world.

Cleaning vs. Sanitizing vs. Disinfecting

Cleaning and sanitizing/disinfection is a two-step process. A surface must first be physically cleaned, typically with soap and water or detergent solution, to remove the dirt from the surface. A surface that has not been cleaned effectively cannot be properly disinfected or sanitized. Once cleaned, the disinfectant is then applied to kill the germs on surfaces. Therefore, all surfaces are typically “touched” twice with two different chemicals. The surface must be able to withstand those chemicals.

Note that soft surfaces, such as woven textile fabric upholstered furniture and carpeting, cannot be disinfected but can be sanitized to “reduce microorganisms of public health concern to levels considered safe, based on established parameters.” The U.S. Environmental Protection Agency (EPA) has not yet recognized a chemical suitable for disinfecting upholstered furnishings. Such furnishings can be sanitized but not disinfected.

Proper Cleaning Procedures: The Label is the Law

The EPA regulates pesticides at the national level, which includes chemical disinfectants for hard surfaces that are manufactured with strict labeling requirements. The EPA-approved labeling will provide users with information including, but not limited to, surface compatibility, dwell times, appropriate application methods, kill claims, and safety information for proper handling.

In order for disinfectants to be effective, strict adherence to the label is essential, but not necessarily abided to in the field. The chemical must be appropriate for the surface. The vast majority of disinfectants are typically formulated for use on hard non-porous surfaces and not intended for use on soft surfaces. When used, these chemicals can damage coated upholstery fabrics. While coated fabrics are considered non-porous, they are in fact soft surfaces.

Once the surface has been cleaned, a disinfectant is applied to the surface for the appropriate amount of time (i.e., dwell time) to kill the microorganisms which it claims to be effective against. The dwell time, defined as the amount of time a disinfectant must remain wet on a surface, is dependent on the specific chemical disinfectant and can vary between 30 seconds to 10 minutes as listed on the product label.

The amount of time the disinfectant is wet on the surface, in order to meet the dwell time, may impact the fabric. In addition, as cleaning professionals often have limited time to clean, these surfaces are often not kept wet for the required dwell time or rinsed off as required by the manufacturer’s instructions, contributing to accelerated surface material degradation.

[Related: Felt: A Mythic Material for Modern Times]

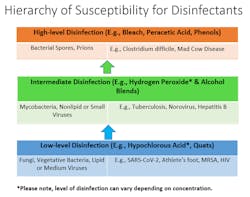

All disinfectants are not the same. There are a handful of different active ingredients utilized for disinfection purposes. These active ingredients react differently when it comes to material compatibility as certain disinfectants can be corrosive and cause visible damage, like tarnishing, clouding or cracking with long-term exposure effecting the material integrity.

Therefore, when selecting a disinfectant, it is crucial to choose a disinfectant less likely to degrade the surface to which it is applied. This can be determined through proper validation and testing. Testing associations have provided healthcare designers with testing information to inform durable coated fabric product selection, i.e. CFFA-Healthcare-201B.

Impacts Due to the Pandemic

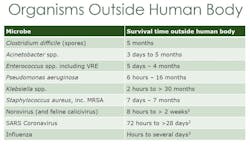

In light of the pandemic, we are cleaning more often with more caustic chemicals. A wide range of disinfectants are effective against SARS-CoV-2, the virus that causes the disease COVID-19. The EPA has compiled a list of all disinfectants effective against SARS-CoV-2 that are listed on EPA’s List “N,” including each product’s active ingredient. Interestingly, SARS-CoV-2, an enveloped virus, is recognized to be one of the very easiest pathogens to kill off a surface. Therefore, it is unnecessary to use harsh or irritating disinfectants, such as bleach. Lower-level disinfectants may be more compatible with materials as well as a safer choice for workers and occupants, while still successfully killing SARS-CoV-2 on surfaces.

The Centers of Disease Control & Prevention (CDC) guidelines state that emergency temporary standards require increased frequency of cleaning and disinfection, with emphasis on high touch surface areas. Due to this enhancement, cleaning and disinfection procedures are being performed with a much higher frequency, likely resulting in the premature breakdown of coated upholstery fabrics that we have seen in healthcare, now in other types of facilities.

The pandemic has also brought forth a number of disinfection technologies to ease the workload that comes with frequent cleaning and disinfection. For example, ultraviolet germicidal radiation (UVC), which has been used traditionally in healthcare settings to disinfect hard surfaces, is now becoming more widespread in other types of facilities. Alternative disinfection application methods in lieu of traditional wiping, such as the use of accelerated hydrogen peroxide vapor and electrostatic sprayers, have also flooded the market. The known long-term effects these technologies will have on materials such as furniture and flooring is minimal and research is ongoing.

Thinking Long-Term

The pandemic has brought unintended consequences. More frequent cleaning combined with the overuse of caustic and hazardous chemicals has brought premature material breakdowns. We have seen these failures in healthcare facilities and anticipate these same failings in other sectors. Design industry collaboration is the key in finding real-world solutions and has resulted in the creation of tools to help the designer specify materials that meet minimal performance standards, the Durable Coated Fabric Programming and Selection Guide for Healthcare and the CFFA-Healthcare-201 certification.

It is essential that designers and suppliers are aware of facility-specific cleaning protocols, the chemicals being used, and the application method when specifying coated upholstery and furnishings in any type of facility. Likewise, it is encouraged that designers reach out to the coated fabric manufacturers to validate compatibility with the specific cleaner, sanitizer or disinfectant being used by the facility. Understanding the long-term impacts of continuous cleaning and disinfection on material compatibility must remain a focus of the design and furniture industry as enhanced and more frequent cleaning will remain beyond the pandemic and for years to come.

Read Next: How to Specify for the Retail Market